You’re sweating, your AC is blowing warm air, and the repair bill is the last thing you want to think about. Before you panic, know this: the problem might be a simple refrigerant issue. But diagnosing and fixing it requires a specific, crucial tool that acts as the bridge between your technician and your system’s lifeblood. That tool is the HVAC manifold hose set. Think of it as the stethoscope and IV line for your air conditioner or heat pump. In this guide, I’ll break down exactly what these hose sets do, why they’re non-negotiable for proper service, and what you need to know as a homeowner.

The HVAC Manifold Hose Set: Your System’s Diagnostic Lifeline

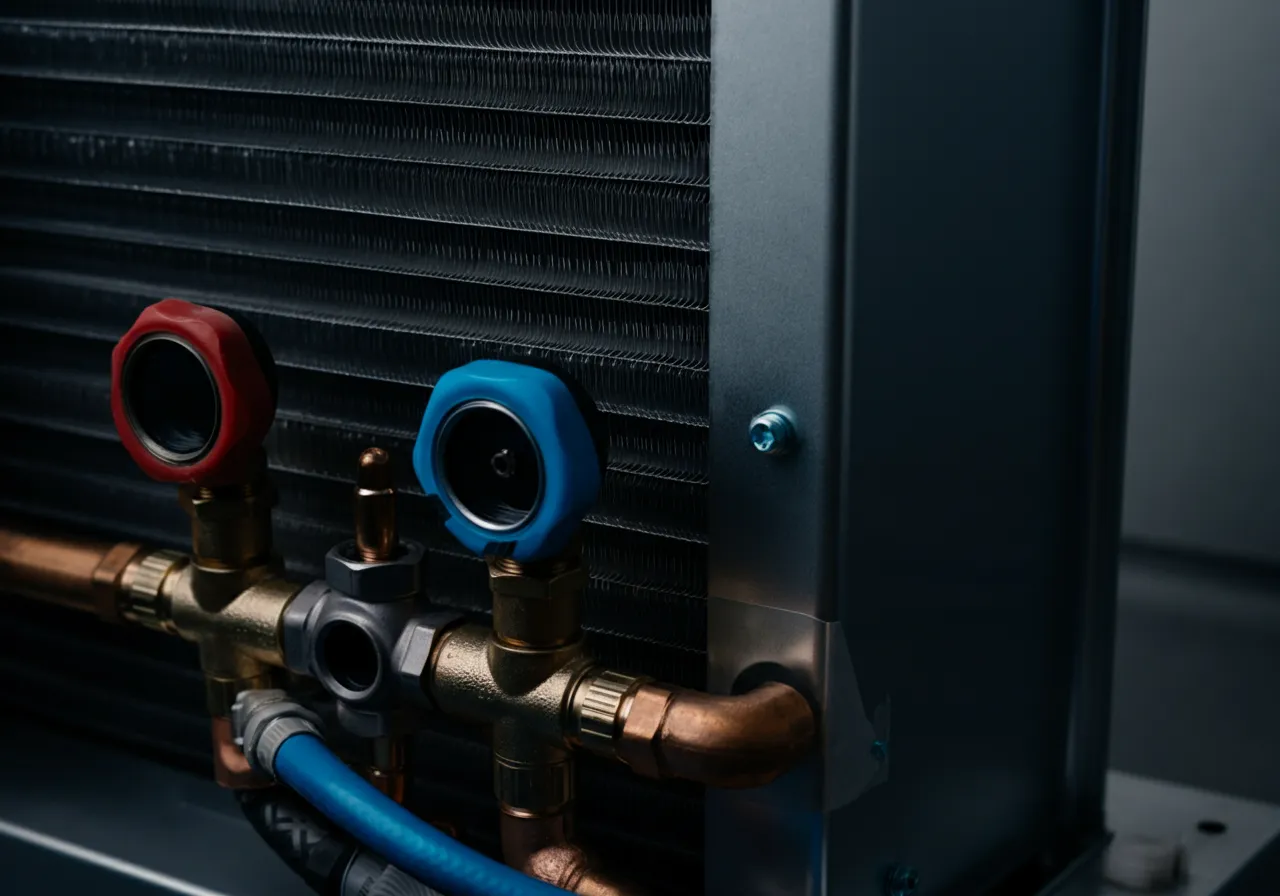

At its core, a manifold hose set is how a technician safely accesses, measures, and adjusts the refrigerant inside your HVAC system. It’s a set of three color-coded hoses (blue, red, and yellow) that connect a manifold gauge to the service ports on your outdoor unit. Without it, we’re working blind. Trying to service an AC without a manifold gauge set is like trying to check your car’s oil without a dipstick—you have no idea what’s really going on inside.

How It Works: The Blood Pressure Cuff Analogy

Let me explain it with a simple analogy. Your HVAC system’s refrigerant circuit is like your body’s circulatory system. The compressor is the heart, and the refrigerant is the blood. The two service ports on your outdoor unit are like arteries we need to check.

- The Blue Hose (Low-Side): This connects to the larger service port (the suction line). It measures the pressure on the “return” side of the system, like checking the blood pressure in your veins.

- The Red Hose (High-Side): This connects to the smaller service port (the liquid line). It measures the pressure on the “supply” side, akin to checking arterial pressure.

- The Yellow Hose (Service/Utility Hose): This is the multi-purpose line. It can connect to a vacuum pump to remove moisture and air, or to a refrigerant tank to add or recover refrigerant. Think of it as the IV line—it’s how we add or remove “fluids” safely.

The manifold gauge in the middle lets us read both pressures simultaneously, giving a complete picture of the system’s health. An abnormal pressure reading tells us exactly where the problem lies—whether it’s a restriction, a leak, or a failing component.

⚠️ Critical Safety Disclaimer

HVAC systems contain high pressures, electricity, and refrigerants that require special handling. This article is for informational purposes only. Only EPA-certified professionals with the proper training, tools, and safety equipment should ever attempt to connect a manifold hose set, recover refrigerant, or perform repairs. Incorrect procedures can cause severe injury, system damage, or result in significant EPA fines for illegal refrigerant release.

Breaking Down the Manifold Hose Set: What Makes a Good One?

Not all hose sets are created equal. As a pro, I look for durability, safety, and compatibility. Here’s what matters:

1. Hose Material and Barrier

The best hoses have a nylon barrier inside the rubber. This prevents refrigerant molecules (especially smaller ones like R-410A and R-32) from permeating through the hose walls. Permeation leads to inaccurate readings and is bad for the environment. Look for hoses rated for the refrigerant you use most.

2. Valve Depressors & Seals

The fittings on the end of the blue and red hoses have a small pin inside called a valve depressor. This safely opens the Schrader valve on your system’s service port. Quality sets have precisely machined depressors and robust O-ring seals to prevent leaks the moment you connect.

3. The Manifold Gauge Itself

The manifold is the brain. A good one has:

- Easy-to-read, accurate gauges with clear scales for different refrigerants.

- Smooth-operating handwheels to open and close access to the hoses.

- Relief valves for safety in case of over-pressurization.

Comparison: Key Features for Different Refrigerants

| Feature | Older R-22 Sets | Modern R-410A Sets | Newer R-32 / HFO Sets |

|---|---|---|---|

| Max Pressure Rating | ~800 PSI | ~1000 PSI (Essential) | ~1000 PSI+ |

| Hose Barrier | Often Standard Rubber | Nylon Barrier Highly Recommended | Nylon Barrier Required |

| Fitting Seals | Standard O-rings | HNBR or similar O-rings | Specialized O-rings for HFOs |

| Primary Use | Legacy Systems | Current Standard | Higher Efficiency Systems |

Pro Tip: If you service systems with various refrigerants, invest in dedicated hose sets for each type, especially for R-32. Cross-contamination of refrigerants is a serious issue. The EPA’s Section 608 rules strictly govern refrigerant handling and require proper equipment.

Signs Your Technician’s Hose Set (And Service) Is Up to Snuff

You can’t do the work, but you can be an informed consumer. Here’s what proper use looks like:

- Clean, Labeled Equipment: Hoses should be in good condition, not cracked or overly stiff. Gauges should be clean and legible.

- Vacuum is Pulled: Any time the system is opened (for a repair), the technician MUST connect a vacuum pump via the yellow hose to remove air and moisture. This is a non-negotiable step that should take 30 minutes to an hour.

- No “Topping Off”: A professional uses the gauges to diagnose a problem, not just to blindly add refrigerant. If your system is low, there is a leak that must be found and repaired.

FAQ: Your Manifold Hose Questions Answered

Can I buy a manifold gauge set and recharge my own AC?

No, and you should not try. While you can purchase the tools, EPA law requires a certification (Section 608) to handle refrigerants legally. More importantly, improper charging can severely damage your compressor, leading to a repair cost far higher than a professional service call. It’s a specialized medical procedure for your home, not a DIY oil change.

Why are there different colored hoses?

The colors (Blue for Low, Red for High, Yellow for Service) are a universal industry standard for safety and speed. It prevents dangerous cross-connections. Imagine hooking the high-pressure line to the wrong port—it could blow a gauge or cause an injury. The color code keeps everyone on the same page.

How often do these hoses need to be replaced?

For a professional, hoses are wear items. They should be inspected before every use for cracks, bulges, or loose fittings. A good set with proper care can last years, but the seals and valve depressors may need periodic replacement. We also perform a “leak check” on the hoses and gauges themselves periodically to ensure accuracy.

The Bottom Line

The HVAC manifold hose set is the fundamental link between a technician’s expertise and the hidden world inside your cooling system. It’s a tool of precision, safety, and diagnosis. Understanding its role helps you appreciate the skill involved in proper HVAC service and ensures you can recognize when a job is being done right. When your comfort is on the line, that peace of mind is priceless. Leave the manifold work to the certified pros, but now you know exactly what they’re doing when they hook up those colored hoses.