You just paid for a new air conditioner or a major repair. The technician pulls a vacuum, waits a bit, and says, “Looks good.” But how do you really know the system is clean, dry, and ready to run for the next 15 years? The truth is, without the right tool, you’re just hoping. That tool is a digital micron gauge, and it’s the single most important device for ensuring a long-lasting, efficient HVAC system.

The “Why”: Moisture is the Silent Killer

Think of your air conditioner’s sealed refrigerant circuit like a perfectly preserved jar of pickles. The lid (the vacuum) keeps everything inside stable for years. Now, imagine that jar has a teaspoon of water and a few breadcrumbs (air) in it before you seal it. What happens? The pickles spoil quickly. That’s exactly what moisture and non-condensable gases (air) do inside your AC.

Moisture mixes with refrigerant and oil to form acids that eat away at the compressor—the heart of your system. It also freezes into ice at the expansion valve, blocking flow and killing efficiency. A proper vacuum removes all air and vapor, but your standard manifold gauges can’t measure it accurately. They might read “0 psi,” but that’s like using a yardstick to measure the width of a hair. A digital micron gauge measures in microns (one-millionth of a meter), giving you the precision needed to know, beyond a doubt, that the system is truly dry.

⚠️ Safety & Professional Disclaimer

Evacuating and charging an HVAC system involves high pressures, electricity, and controlled substances. This work should only be performed by EPA-certified and licensed HVAC professionals. This article is for informational purposes to help homeowners understand the process and importance of proper evacuation. Incorrect handling can cause system failure, personal injury, or violate federal law.

Beyond the Bubble Test: How a Micron Gauge Works

For decades, technicians relied on the “vacuum hold” test, watching a gauge to see if pressure rose over 15 minutes. It was better than nothing, but it was slow and imprecise. A modern digital vacuum gauge uses a piezoelectric sensor. Here’s a simple analogy:

Imagine blowing up a balloon. The pressure inside is high, and it’s easy to measure. Now, let almost all the air out. Feeling the tiny, residual pressure with your fingers is impossible. A micron gauge is like a super-sensitive microphone that can “hear” the faintest whisper of vapor molecules bouncing around inside the deep vacuum of your AC lines. It translates that activity into a digital readout. When the number stops falling and holds steady below a critical threshold, you know evacuation is complete.

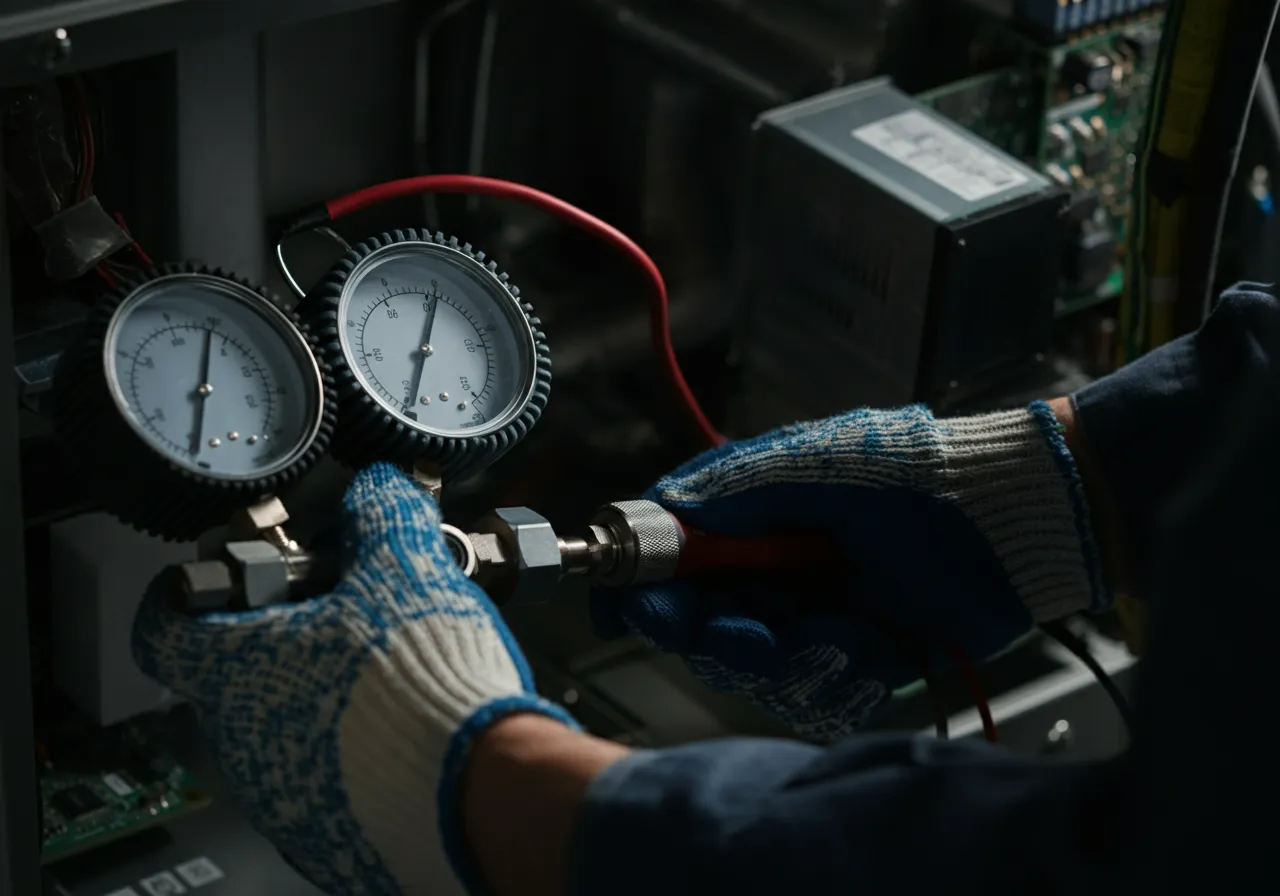

The Step-by-Step: How a Pro Uses a Digital Micron Gauge

Here’s a look at the proper procedure a qualified technician will follow to ensure a clean, dry system during installation or repair.

Tools You’ll See Them Use:

- High-quality vacuum pump (CFM rating appropriate for the system)

- Digital micron meter with a fresh sensor

- Core removal tools (for access valves)

- Clean, vacuum-rated hoses (short and wide, 3/8″ or larger)

- Manifold gauge set (often used only for charging, not vacuuming)

The Critical Steps:

- System Preparation: All repairs are complete, schrader cores are removed from the service ports, and the system is assembled with the vacuum pump and micron level gauge connected via a dedicated port.

- Initial Pull-Down: The pump is started. The gauge will quickly drop from atmospheric pressure (760,000 microns) down to the 1,000-10,000 micron range as bulk moisture is removed.

- The Deep Vacuum & Decay Test: This is where the digital readout is essential. The technician isolates the pump and watches the micron reading on the system side.

- A good system will achieve a reading below 500 microns (many manufacturers specify 250-500).

- More importantly, the reading must hold stable or rise very slowly after isolation. A rapid rise indicates a leak or significant moisture still boiling off (outgassing).

- Triple Evacuation (Best Practice): For ultimate dryness, pros may introduce a small amount of dry nitrogen, break the vacuum, and repeat the process 2-3 times. This helps flush out trapped moisture.

- Final Verification: Once the system holds a deep vacuum (e.g., 250 microns) stable for 15-30 minutes, it is proven dry and tight. Only then is it ready for refrigerant charging.

Symptoms of a Poor Vacuum (Problems You’ll Notice Later)

If a system was charged without a proper vacuum check, you might experience:

- Reduced Cooling & High Bills: Moisture causes freeze-ups and inefficient operation.

- Compressor Failure: Acid formation from moisture is the leading cause of premature compressor death.

- Erratic Operation: Ice blocks, pressure swings, and tripped safety controls.

Choosing a Gauge: Key Features for Pros

Not all micron gauges are equal. Here’s what matters in a professional tool.

| Feature | Why It Matters |

|---|---|

| Sensor Type & Speed | Piezoelectric sensors react faster than older thermistor types, giving real-time feedback during decay tests. |

| Resolution & Accuracy | Look for 1-micron resolution. Accuracy of +/- 5-10% is standard for field tools. |

| Valve & Hose Port | A built-in isolation valve lets you isolate the sensitive sensor from the pump, protecting it and allowing for true decay testing. |

| Durability & Display | Rugged casing and a clear, backlit display are essential for bright job sites. |

For an in-depth look at vacuum pump and gauge technology from an industry leader, you can read this resource from ACHR News, a reputable trade publication.

FAQ: Your Digital Micron Gauge Questions Answered

1. What is a “good” micron level for my AC?

Most equipment manufacturers require a vacuum level of 500 microns or lower, with many specifying 250-350 microns. The key is not just hitting the number, but having it hold stable, proving no leaks or moisture remain.

2. Can I just use my manifold gauges to pull a vacuum?

No. Manifold gauges are not accurate enough in deep vacuum ranges. They might read “0” or “29.9 inHg,” but that’s a wide range that can still contain harmful moisture. A dedicated micron vacuum gauge is non-negotiable for quality work.

3. How long should a vacuum take?

There’s no fixed time. A small residential system might reach 500 microns in 15-20 minutes with good equipment. However, the decay test (watching the level hold) is more important than the initial pull-down time. A system with a lot of moisture may take an hour or more to fully outgas.

The Bottom Line

Asking your technician, “Did you use a micron gauge to verify the vacuum?” is one of the smartest questions a homeowner can ask. It separates the quick-and-dirty jobs from the quality installations meant to last. That little digital screen is your guarantee that the “jar” is truly sealed, protecting your investment for years to come.