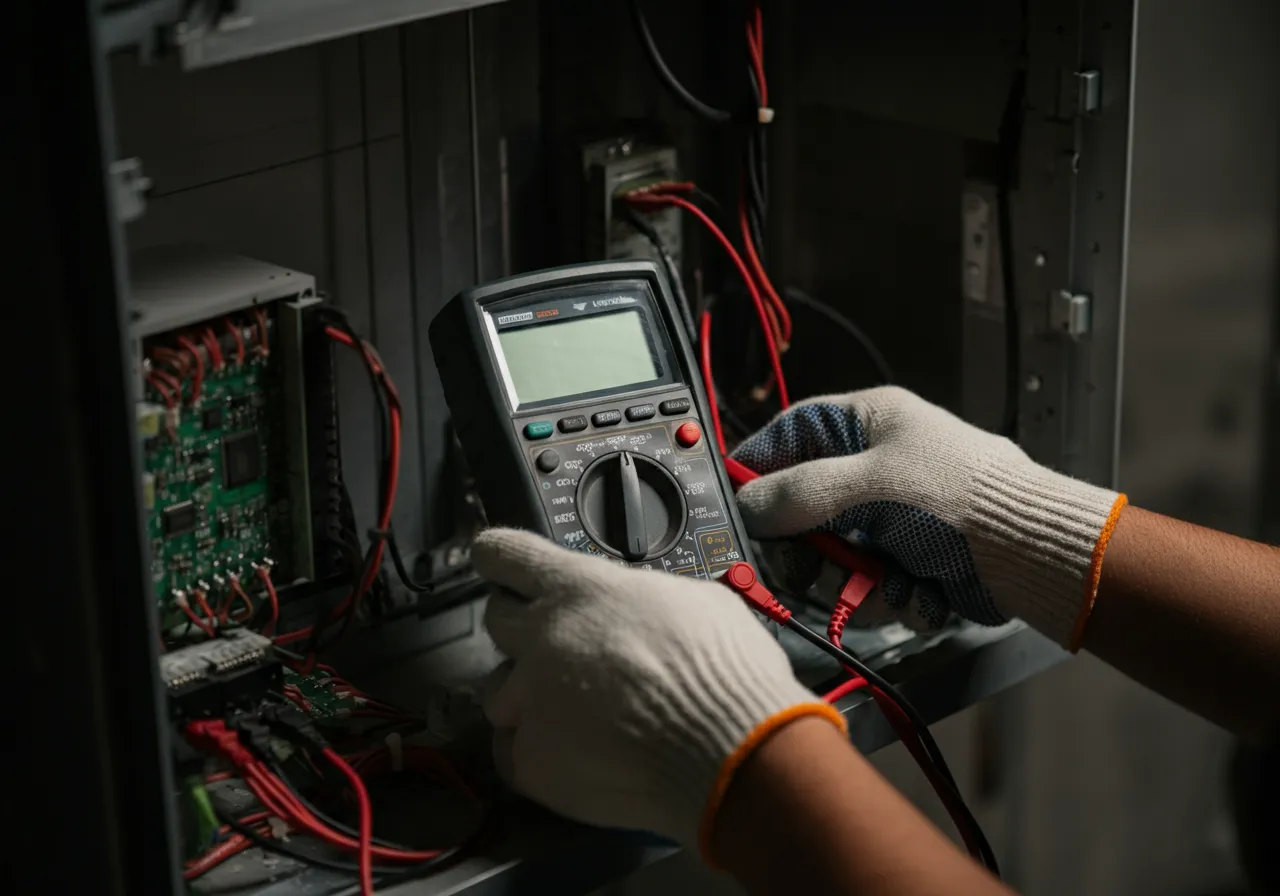

You hear the dreaded click from your thermostat, but your air conditioner or furnace doesn’t respond. Or maybe it starts, only to trip the breaker a few minutes later. Before you call for service, there’s a crucial tool that can help you—or your technician—diagnose the problem: an HVAC multi-meter. This isn’t just any multimeter; it’s the specialized detective kit for your home’s climate control system. Let’s break down why this tool is indispensable, how to use it safely, and what to look for when choosing one.

Why Your HVAC System Needs a Special Kind of Meter

Think of your HVAC system as a complex, high-performance engine. It has pumps (compressors), fans (blower motors), and electrical “nervous systems” (thermostats and control boards). A standard multimeter can check for basic power, but an HVAC multi-meter is built for the specific electrical challenges these systems present.

The Technical Analogy: The System’s Vital Signs Monitor

If your HVAC system were a patient in a hospital, the HVAC multi-meter would be the vital signs monitor. It doesn’t just check for a “pulse” (presence of voltage). It measures the precise “blood pressure” (voltage levels), the “heart rate and rhythm” (capacitor microfarads and motor amperage), and checks for “nerve conductivity” (continuity in wires and switches). A general-purpose meter might tell you the patient is alive, but an HVAC-specific meter tells you *why* they’re feeling sick.

⚠️ Critical Safety Disclaimer: Electricity Kills

Working on HVAC electrical components is extremely dangerous. You are dealing with high voltage (240V), high current, and capacitors that can hold a lethal charge even when the power is off. This article is for informational purposes only. If you are not a licensed electrician or HVAC technician with proper training, personal protective equipment (PPE), and knowledge of the National Electrical Code (NEC), do not attempt these procedures. Always turn off power at the disconnect and the circuit breaker, and use a voltage tester to confirm power is OFF before touching any wires. When in doubt, call a professional.

What Makes an HVAC Multi-Meter Different?

While it shares core functions with a standard digital multimeter (DMM), a meter tailored for HVAC/R work has specific features for our trade:

- Microfarad (µF) Range for Capacitors: This is the #1 feature. It allows you to test start and run capacitors—a very common point of failure—by measuring their capacitance and comparing it to the rating printed on the side.

- High Amp Clamp (400A+): HVAC motors (compressor, blower, condenser fan) draw significant current. A clamp meter lets you measure amperage safely without breaking into the circuit, which is essential for checking for overloads or failing motors.

- LoZ (Low Impedance) Voltage Mode: This prevents “ghost voltage” readings from induced voltage in unused wires, giving you a true reading of whether a circuit is live or dead.

- Temperature Probe (Type-K): Useful for checking supply/return air temp splits, superheat, and subcooling (for advanced diagnostics).

- Durability: Built to withstand drops, heat, and moisture common on job sites.

How an HVAC Pro Uses a Multi-Meter: A Step-by-Step Diagnostic Scenario

Let’s walk through a common issue: an outdoor condenser unit not starting. This illustrates the logical flow of using the meter’s functions.

- Safety & Visual Inspection: Turn off power at the disconnect and main panel. Check for obvious issues: burnt wires, damaged capacitor, debris.

- Check Control Voltage (24V): With power restored *only at the panel* and thermostat calling, use the meter’s voltage (V~) setting at the contactor coil terminals. No 24V? The problem is upstream (thermostat, transformer, wire).

- Check Line Voltage (240V): At the contactor, check across L1 and L2 (with power on safely). No voltage? Problem with the disconnect or breaker.

- Test the Capacitor (µF): POWER MUST BE OFF AND CAPACITOR DISCHARGED. Disconnect wires. Set meter to capacitance (µF). Place leads on the HERM and COMMON terminals (for run cap). Reading should be within ±6% of the rating. A low reading means it’s weak; a reading of “OL” or zero means it’s dead.

- Check Compressor Windings (Ohms Ω): With power OFF, at the contactor, disconnect the wires to the compressor. Check resistance between Common, Run, and Start terminals. You should get three readable resistances (e.g., C-R, C-S, R-S). The highest reading should be the sum of the other two. “OL” indicates an open winding; a very low reading (near 0) indicates a short.

- Check for Ground Short (Ohms Ω): Check resistance from each compressor terminal to the copper refrigerant line or ground. It should read “OL” (infinite). Any continuity here means the compressor is grounded and needs replacement.

Choosing the Right HVAC Multi-Meter: A Quick Comparison

| Feature | Basic HVAC Meter (Good for Hobbyists) | Professional-Grade HVAC Meter (Tech Standard) |

|---|---|---|

| Capacitance (µF) Range | Up to 100 µF | Up to 10,000+ µF (for large motor run caps) |

| Amp Clamp | Often a separate accessory | Integrated, True-RMS (400A-1000A) |

| Durability | Plastic case, basic drop rating | Rubberized, high-impact, CAT III/IV safety rated |

| Temperature | Not always included | Type-K probe included |

| Price Range | $80 – $150 | $200 – $500+ |

| Best For | Homeowners with advanced DIY skills, basic capacitor/voltage checks | Licensed technicians, full system diagnostics, daily professional use |

For a deep dive into electrical measurements and safety categories for meters, the Fluke guide to digital multimeters is an excellent resource from a leading manufacturer.

HVAC Multi-Meter FAQ

Can I use a regular multimeter on my HVAC system?

You can check for voltage and continuity, but you cannot test capacitors (the most common failure point) without a µF function. For thorough diagnostics, an HVAC multi-meter with a clamp and capacitance is required.

What is the most important setting to use for basic safety?

Always verify the absence of voltage first. Use the AC voltage setting to check between all points you will be working on (e.g., L1 to L2, L1 to ground, L2 to ground) to confirm the power is truly OFF before proceeding.

My meter reads “OL” when testing a component. What does that mean?

“OL” stands for Over Limit or Open Loop. In resistance (Ω) mode, it means there is no continuity—the circuit is open or broken. In capacitance (µF) mode, it typically means the capacitor is dead and not holding any charge. It’s a key diagnostic reading.

Final Thoughts

An HVAC multi-meter is the eyes and ears of a technician inside the electrical heart of your system. While its proper use requires training and respect for safety, understanding what it does demystifies the diagnostic process. Whether you’re a curious homeowner listening to your technician explain a failed capacitor or a new apprentice learning the trade, knowing that this tool measures the vital signs of voltage, current, and capacitance is the first step to understanding—and fixing—what’s wrong. Remember, when dealing with high-voltage HVAC components, there is no substitute for professional experience and safety-first practices.